Services

Services provided by SMS, when bundled with Create3D, give our clients a complete solution. Not only will SMS shape the software to your needs, we can provide data analysis and document outputs that are useful outside of Create3D. From simulation analysis to financial tools, these are the most frequently-used SMS services.

Step Chart

Our financial calculator is designed to export step chart information for manufacturing lines. Step charts are useful graphs that highlight the proper sequence to install machines to provide the highest capacity increase with each machine install. As each new machine is digitally installed, the graph will also show the financial investment required. When cutting back on production, our step charts will also show which machines to uninstall in order to redeploy elsewhere.

Work Content Outputs/Progress Reports

Using our customized controllers, SMS can export progress reports and station component information to Excel. These reports show in detail which station components have been built in 3D and added to your layout. Notes on each station component, such as operator number and location, tool types, and robot information, can also be tracked. This 3D inventory provides our clients with a list of all their assets and their locations.

Program Tracking

As soon as a physical factory enters the building phase, SMS can begin to track the statuses of every machine that will be installed. Using our color-coded boxes, our clients can see at a glance the status of every machine from the purchase order through the delivery to the install and qualification.

CAD Output

SMS has the ability to export our 3D layouts directly to 2D and 3D AutoCAD drawings. We understand that AutoCAD is an industry standard and provide our clients with the option to receive CAD drawings as a deliverable. The different layers in our 3D layouts translate over to color-coded layers in AutoCAD. SMS can also import your CAD drawings directly into our 3D layouts to aid with the 3D build process.

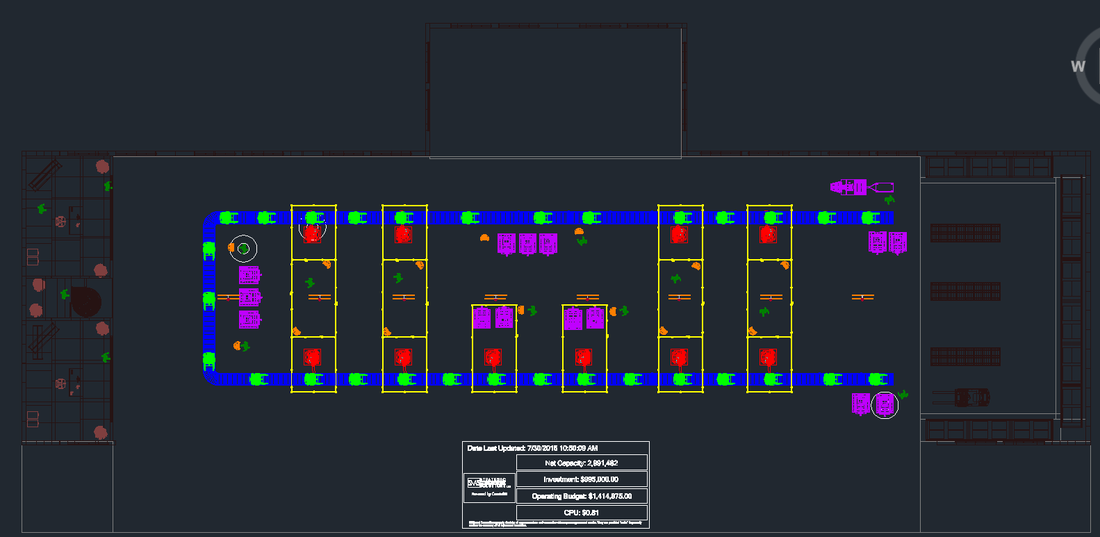

2D CAD Output

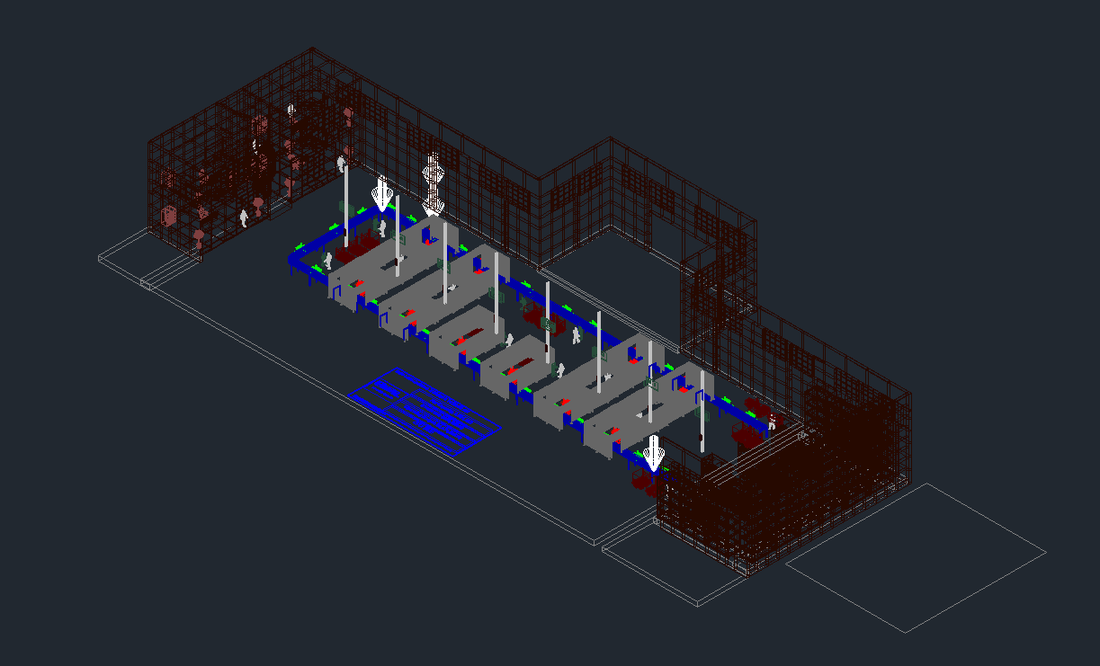

3D CAD Output

Simulation Results

SMS typically runs 30-day simulations but can customize any of our simulation parameters upon request. A massive amount of raw data is exported to Excel upon completion and SMS formats that data into easier-to-read graphs and charts. Using these graphs, SMS can provide information regarding bottlenecks and suggestions to relieve them. Running the same simulations with different pallet numbers, buffer areas or other "what-if scenarios" will provide objective data on which solution will provide the highest output.

Ergonomic Analysis

SMS can run ergonomic analyses on operator processes and offer suggestions to improve the health and happiness of your workers. Using NIOSH standards, SMS can locate problem areas where an operator is likely to be hurt over time. SMS will also run "what-if scenarios" to offer solutions to these problem areas such as adding re-designed material handling units or operator platforms to improve reach.

Customized Solutions

SMS works cooperatively with our clients to develop customized solutions based on unique situations. We've developed custom controllers with customer input to address operator walk path optimization, bills of material, and adjusting our financial calculator based on customer-owned formulas. We are constantly developing new solutions to help our customers solve their one-of-a-kind problems.